30-90BPM Sauce Bottling Machine Condiment Linear Filling Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model NO. | FPL-10 Filling Machine | Feed Cylinder Structure | Multi-Room Feeding |

|---|---|---|---|

| Dosing Device | Plunger | Filling Principle | Pressure |

| Packaging Container Lifting Structure | Chute Pneumatic Combination Lifting | Structure | Linear |

| Packaging | Bottle | Packaging Material | Plastic |

| The Material | Stainless Steel | Transport Package | Packed In Wooden Cases |

| Specification | 2000mmx1500mmx2200mm | Trademark | Jinxing |

| Origin | China Jiangsu | HS Code | 8422301090 |

| Supply Ability | 100 Units A Year | After-sales Service | Site Installation, Site Maintenance |

| Warranty | 12 Months | Type | Piston Filling Machine |

| Automatic Grade | Automatic | Material Type | Liquid |

| Filling Valve Head | Multi-Head | Customization | Available | Customized Request |

| Highlight | 90BPM sauce bottling machine,30BPM sauce bottling machine,Condiment linear filling machine |

||

Condiment Linear Filling Machine

It is suitable for the filling of various liquids, pastes and sauces, such as alcohol, disinfectant, disposable hand sanitizer, honey, chili sauce, tomato sauce, pearl milk tea, orange juice and other materials, with strong versatility; Automatic weighing and packing system for your current and future needs! The functions of the packing system mainly are conveying, weighing, filling and bag sealing. Realize automatization, save labor and increase the output.

A. Powder Packing Solution

Servo Screw Auger Filler is specialized for powder filling such as nutrients powder, seasoning powder,

flour, medicinal powder, etc.

B. Liquid Packing Solution

Piston Pump Filler is specialized for liquid filling such as water, juice, laundry detergent, ketchup etc.

C. Solid Packing Solution

Combination multi-head weigher is specialized for solid filling such as candy, nuts, pasta, dried fruit and vegetable etc.

D. Granule Packing Solution

Linear weigher is specialized for granule filling such as chemical, beans, salt, seasonings etc.

1, widely used in filling machinery, especially suitable for fine and complex materials.

2. Fast filling speed.

3, exquisite and compact, easy to mirror or pipeline layout

4. The special sealing design at the bottom of the filling mouth prevents leakage during filling.

5. Chamfering structure at the bottom of filling head. With fixed effect, can be submerged into the bottom of the bottle filling.

6. With motor control, the filling valve can rise synchronously with the liquid level, effectively reducing foam generation.

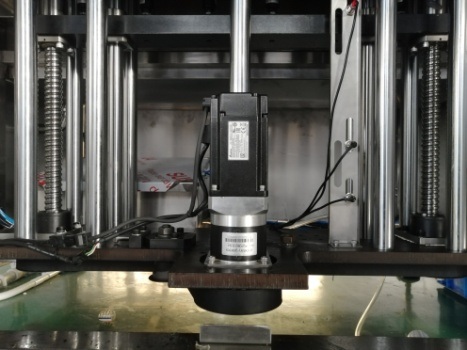

As shown in the picture, the cylinder liner is mounted on the top of the worktable, and the one-button piston decylinder design provides much more flexibility than the traditional non-removable and cleanable cylinder liner, making it easier to clean and replace seals.

1, fast speed, high precision, good stability;

2. High speed filling is used in the initial stage of filling. When filling volume is close to the target, slow filling can be used to prevent liquid overflow pollution bottle mouth;

3, easy to adjust, filling specifications only need to change the parameters on the touch screen, dose adjustment can also be adjusted on the touch screen;

4, compared with the traditional filling method, servo motor driven machine is not affected by the change of compressed air pressure, higher production efficiency.

Automatic Filling machine is controlled by computer via an auxiliary device (such as a cylinder block bottle system, stop bottles system, lifting system, feeding control, counting devices, etc.) to complete the automatic filling in the absence of personal operating conditions.

| Filling Nozzle | 4 Nozzle | 6 Nozzle | 8 Nozzle | 10 Nozzle | 12 Nozzle | 16 Nozzle | 18 Nozzle |

| Filling Speed | 30 bot/min | 40 bot/min | 50 bot/min | 60 bot/min | 70 bot/min | 80 bot/min | 90 bot/min |

| Filling Volume | 50-500ml, 100-1000ml | ||||||

| Filling Accuracy | ±0.5-1% | ||||||

| Power Voltage | 220V,50/60Hz,2Phase;380V, 50/60Hz, 3 Phase | ||||||

| Air Consumption | 0.6-0.8Mpa | ||||||

| Remark | 1. Filling speed is 500ml/ bottle of water. 2. Filling speed will be different due to different material characteristics. 3. More options can be customized according to your requirements. |

||||||

Changzhou Jintan Jinxing Machinery Co., LTD., founded in 2004, is located in The Yangtze River Delta Economic development Zone changzhou Jintan District, is engaged in packaging machinery products manufacturing, sales and import and export business as one of the intelligent equipment manufacturing enterprises.

The main products of the company are rational bottle machine, bottle washing machine, filling machine, capping machine, labeling machine, packing machine, palletizing machine, etc.

The company is mainly engaged in pesticide chemical industry, petrochemical industry, cosmetics, medicine, food industry intelligent workshop overall solution and landing turnkey project business. The company attaches importance to independent innovation, product technology and quality in the domestic industry in an important position, with leading technical innovation ability and high-quality staff team for domestic and foreign customers to provide a number of reliable packaging production line automation overall personalized solutions.

Our services

The sample service

1. We can send you the production video of the machine.

You are welcome to visit our factory at any time. You can see the machines in operation here. We'll arrange to pick you up when you come.

Customized service

1. We can design the machine according to your requirements (material, power, filling type, bottle type, etc.).

2. We will also give you professional advice.

After-sales service

1. We will provide the BILL of lading in time to ensure that you can get the qualified machine quickly.

2. After you complete the preparation conditions, our engineers will go to your factory for installation, testing and training.

We provide one year warranty, free of charge to provide vulnerable parts.

Successful cases

Through efficient cost control, we find the right balance with our customers: diversified production range, high-end packaging form. At the same time, the efficient operation of equipment improves the market competitiveness of enterprises. Wangji will provide customers with customized beverage production line solutions, including bottle design, label design, beverage preparation, packaging system and advertising solutions of the best solutions, to help customers easily start businesses, easy access to the market.