Spray Pump Rotary Capping Machine Automatic Alcohol Disinfectant Bottle

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model NO. | SCP-12 | Usage | Inner Packing |

|---|---|---|---|

| Type | Packaging Sealing Machine | Packaging Material Mechanical Properties | Flexible Container Sealing |

| Material Type | Liquid | Automatic Or Not | Fully Automatic |

| Machine Material | Stainless Steel | Transport Package | The Wooden Case |

| Specification | 2000mmx1500mmx2200mm | Trademark | Jinxing |

| Origin | China Jiangsu | HS Code | 8422301090 |

| Supply Ability | 100 Units A Year | After-sales Service | Site Installation, Site Maintenance |

| Warranty | 12 Months | Packaging | Box |

| Automatic Grade | Automatic | Packaging Material | Bamboo, Wood |

| Application | Cosmetics, Cleaning, Detergent, Drinks, Oil, Dairy Products, Skin Care Products, Hair Care Products, Tea, Seasoning | Customization | Available | Customized Request |

| Highlight | 220V Rotary Capping Machine,380V Rotary Capping Machine,Automatic rotary filling and capping machine |

||

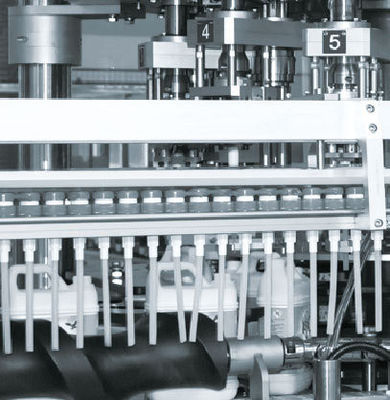

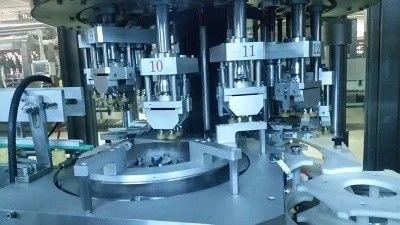

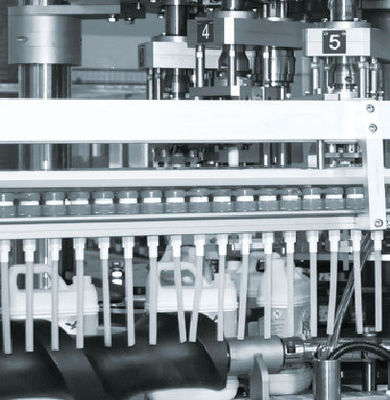

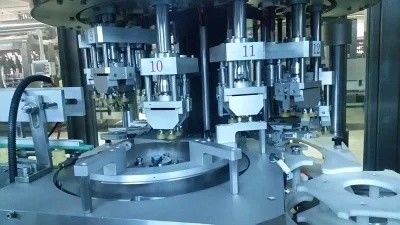

1. With novel design philosophy, its manufacture, safety performance are carried out according to European standards and conform to GMP requirement as well. 2. It is furnished with highly efficient filters of international famous brands to effectively ensure sterility and cleanness of class-A area. Air blower, filter and other equipment adopt sinking-type design structure to realize easy, reliable overhaul and replacement. 3. Materials adding is completely isolated from operating area. Those areas requiring artificial interference are furnished with glove boxes to prevent class-A area from being destroyed. 4. Through machine-gas -electricity combination, full-automatic operation can be realized including bottles entering, filling, adding of inner corks and outer caps, caps tightening and sorting of defective. 5. Filling adopts high-precision ceramic plunger pumps or peristaltic pump structure. High-precision filling volume, non-leakage and high efficiency are ensured through servo drive quantification. 6. Bottle mouths are added with inner corks. Outer caps adopt structure of mechanical hands to ensure accurate positioning fast and efficient adding of caps.

| Type: | Capping Machine, Capping Machine | Applicable Industries: |

Hotels, Restaurant, Home Use, Retail

|

| Machinery Test Report: |

Provided

|

Video outgoing-inspection: |

Provided

|

| Core Components: |

PLC, Bearing, Motor

|

Marketing Type: |

New Product 2020

|

| Application: |

Beverage, Chemical, Commodity, Food, Machinery & Hardware,

|

Warranty of core components:

|

12 months |

| Automatic Grade: |

Automatic

|

Voltage:

|

220VAC/380VAC |

| Packaging Type: |

Wooden Case

|

Brand Name:

|

Jinxing |

| After-sales Service Provided: |

Engineers available to service machinery overseas, Field installation, co

|

Qualified rate of capping: |

99.9%

|

| After Warranty Service: |

Video technical support, Online support, Spare parts, Field mainte

|

Air operated source: |

0.6Mpa clean and stable compressed air

|

Major Characteristics:

1. Support product customization, any requirements you need can be customized according to your requirements.

2. Sample test on our machine.

3. Provide business consulting and technical support, as well as a free professional filling solution

4. Make a machine layout for customers based on customers' factories.

After-sales service

1. Manual book.

2. Videos of installation, adjusting, setting, and maintenance, are available for you.

3. Online support, or face-to-face online communications, are available.

4. The engineer overseas services, are available. The tickets, visa, traffic, living, and eating, are for customers.

5. During the warranty year, without human-being broken, we will replace a new one for you.

The sample service

1. We can send you the production video of the machine.

You are welcome to visit our factory at any time. You can see the machines in operation here. We'll arrange to pick you up when you come.

Customized service

1. We can design the machine according to your requirements (material, power, filling type, bottle type, etc.).

2. We will also give you professional advice.

After-sales service

1. We will provide the BILL of lading in time to ensure that you can get the qualified machine quickly.

2. After you complete the preparation conditions, our engineers will go to your factory for installation, testing and training.

We provide one year warranty, free of charge to provide vulnerable parts.

Successful cases

Through efficient cost control, we find the right balance with our customers: diversified production range, high-end packaging form. At the same time, the efficient operation of equipment improves the market competitiveness of enterprises. Wangji will provide customers with customized beverage production line solutions, including bottle design, label design, beverage preparation, packaging system and advertising solutions of the best solutions, to help customers easily start businesses, easy access to the market.

FAQ:

Frequently asked Questions:

Q1. May I visit your factory?

A1: Ok, our factory address: No.158 Huaxing Road, Jintan, Changzhou city, Jiangsu Province, China.

Q2. If we have a new product sample, could you help analyze and design the machine?

A2: Yes, our technicians can help analyze, design and test the new products you offer.

Q3. What can you buy from us?

A3: Bottle unscrambling machine, bottle washing machine, filling machine, capping machine, labeling machine, unpacking machine, packing machine.

Q4. What spare parts can you provide?

A4: After we have installed all the equipment, we will send you a list of spare parts for your reference.

Q5. What services can we provide?

A5: Delivery terms accepted :FOB,FCA,EXW;

Currency of payment accepted: USD, Euro;

Payment methods :T/T, TELEgraphic transfer, PayPal;

Language: English, Chinese